uhmw friction coefficient

The molecular weight for the thermoplastic ranges from 31 million to 100 million grams per mole. Knee hip and spine replacements Skis and snowboards Hydraulic seals and bearings Military vehicle and body armor Acetal Resin.

While it has a significantly lower coefficient of friction than acetal it doesnt boast the same creep resistance.

. It is recommended for use at temperature ranging from -250C to 82C. F max μ F n where F max Frictional force N lb μ static μ s or kinetic μ k frictional coefficient F n. UHMW PE Sliding Panel Rubber Elements Marine Boat Fenders Dock Plate UHMW PE Material UHMW-PE is the best material for its low rate of friction coefficient abrasion resistance and great anti-impact ability so it is very suitable to be the material of marine fenderThe advantages of HDPE Panel.

Both plastics in their natural form are white and both are widely stocked by most plastics distributors. Friction coefficient of UHMW and HDPE. UHMW does not protect against acidity as well as galvanization or stainless steel however.

It reduces noise and vibration is chemical-resistant and non-toxic and offers excellent mechanical properties even in cryogenic conditions. Virgin natural UHMW has a continuous use temperature rating of 180 degrees F and coefficient of friction of 15-20 static 10-20 dynamic and complies with FDA USDA EU102011 standards. As a result it wont be easy to melt it making it perfect for high.

Redco UHMW plastic is known for its durability machinability versatility and cost-effectiveness. 012-020 kinetic when used on steel. It has a.

Coefficient of Linear Thermal Expansion. Starwheels bushings bumpers chain guides wear stripes wear plates Sprockets guide rails. They have values of friction coefficient for HDPE and UHMWPE.

Its coefficient of friction is very low 015 -020 static. Thickness ranges from 010 up to 12 thick plate and rod from ¼ diameter to 12 diameter. Low coefficient of friction.

It also is the best material for minimizing stiction. Kjoiner Mechanical OP 1 Nov 02 1533. UHMW is available in sheet rods tubular bars tape wear strips angles and profiles.

UHMW is an excellent choice for many industrial applications. Unfortunately the tensile strength is low 4300 psi 267 MPa so you will need more material to carry the same load. UHMW is commonly manufactured in Natural FDA approved black and repro black.

Its biggest downside though is its thermal properties. It looks like the coefficient for HDPE is 28 vs 15 for UHMW. Both plastics are FDACFIA compliant in their natural form.

They do not degrade or rot and are easily recycled at the end of their useful service life. Coefficient of linear thermal expansion. Non-Toxic and smell 2.

The extremely low coefficient of friction of UHMW makes it a very slippery plastic and enhances its wear characteristics. Virgin UHMW is FDA compliant and is used in applications where high levels of friction are likely to arise including chain channel wear strips belt scrapers guides and rollers. Coefficient of Friction.

D648-250 - Maximum continuous service temperature in air F. PROPERTY ASTM TEST UNITS METRIC US 030 060 125 Density D792 gmcc 093 093 093 Tensile Strength Yield D638 MPapsi 233300 202964 223227 Tensile Strength Break D638 MPapsi 537740. UHMW Polyethylene UHMW is known for its excellent abrasion resistance and low coefficient of friction.

Both plastics are known for having a very low coefficient of friction and net zero water absorption. It is also often used as conveyor guide rails chute liners shelf liners belt scrapers chain guides and guide rails suspension wear plates sprockets wheels bearings. UHMW rod comes in diameters that range from 12 to 12 inch 10-feet long.

87 rows Coefficient of Friction Equation and Table Chart Design Resources Friction Design Data The frictional force for Static Friction can be expressed as. Thanks for the link. It is also very resistant to moisture most chemicals UV radiation and micro-organisms.

Other properties that make UHMW attractive is its. Water absorption immersion 24 hours D570. Non-toxic Low coefficient of friction Corrosion abrasion wear and impact resistant Extremely low water absorption.

UHMW is advantageous in that its a low-cost low-weight solution. FQ1000 UHMW-PE materials are compounded to resist ozone and UV radiation. UHMW is available in sheet tubes rod and profiles.

UHMW is adaptable to many industrial applications thanks to its durability lightweight chemical resistance low friction and one of the highest recorded impact strength in any thermoplastic material. Theyre both available in 48 wide plates and in common thicknesses from 18-2 and beyond. Features Very low friction coefficient Excellent abrasion resistance UV and ozone resistant Does not rot split or crack 100 recyclable Applications Fender panel frame face pads.

M2 weight of conveyed objects f1 coefficient of friction when chain etc are returning f2 coefficient of friction when chain etc are conveying f3 coefficient of friction when conveyed objects are moving g gravitational constant 11 sprocket losses due to directional changes of the chain. UHMW is white in color and easy to machine. As it is made from FDA grade materials it is a preferred material in food packaging applications.

Comparison of dynamic coefficient of friction on polished steel. Polyslick UHMW Sheet exhibits the properties of excellent impact strength abrasion resistance low coefficient of friction as well as very good chemical resistance. As an added benefit it has a low coefficient of friction and depending on how its installed can be easy to renew.

Redco UHMW can be machined into virtually anything from small bearings to large sprockets and liner. The material is ideally suited for wear applications especially in contact with metals. UHMW is used in.

Meets ASTM-D-4020-81 of 40 to 54- million molecular weight Description UHMW has a very low coefficient of friction. This industrial grade material is also moisture stain and odor resistant and is FDA approved to be used in the food processing industry. Heat deflection temperature 66 psi264 psi F.

UHMW also displays extraordinary resistance to abrasive wear by gritty materials. M1 weight of the chain etc.

Coefficient Of Friction Of Uhmwpe With Fillers Download Scientific Diagram

Pdf Ultra High Molecular Weight Polyethylene Uhmwpe As A Promising Polymer Material For Biomedical Applications A Concise Review Semantic Scholar

Uhmw Polyethylene Redwood Plastics It S 20 Times Stronger Than Steel But Flexible And Slippery Plastic Sheets Renewable Energy Resources Off Grid Living

Coefficients Of Friction Of Various Uhmwpe Materials Download Scientific Diagram

Uhmw Pe Roller Plastic Roller Conveyor Roller Scandi Co Ltd

Uhmw Plastic Jig Stock 3 4 Thick Jig Drill Guide Jig Molds

The Cof Of Uhmwpe For Different Aging Times Reprinted With Permission Download Scientific Diagram

Pin On Custom Plastic Extrusion

Uhmw Pe Roller 20210216 Pt Shj Tek Web Rev 1

Polymers Free Full Text Ultra High Molecular Weight Polyethylene Uhmwpe As A Promising Polymer Material For Biomedical Applications A Concise Review Html

Friction Coefficient And The Static Mechanical Characteristics Of A Download Table

The Coefficient Of Friction Cof Of Uhmwpe For Different Aging Times Download Scientific Diagram

The Friction Coefficient Of Uhmwpe Under Lubrication And Download Scientific Diagram

Polyethylene A Ultra Haut Poids Moleculaire Pe Uhpm In 2022 Friction Tape Table Saw Jigs Jig

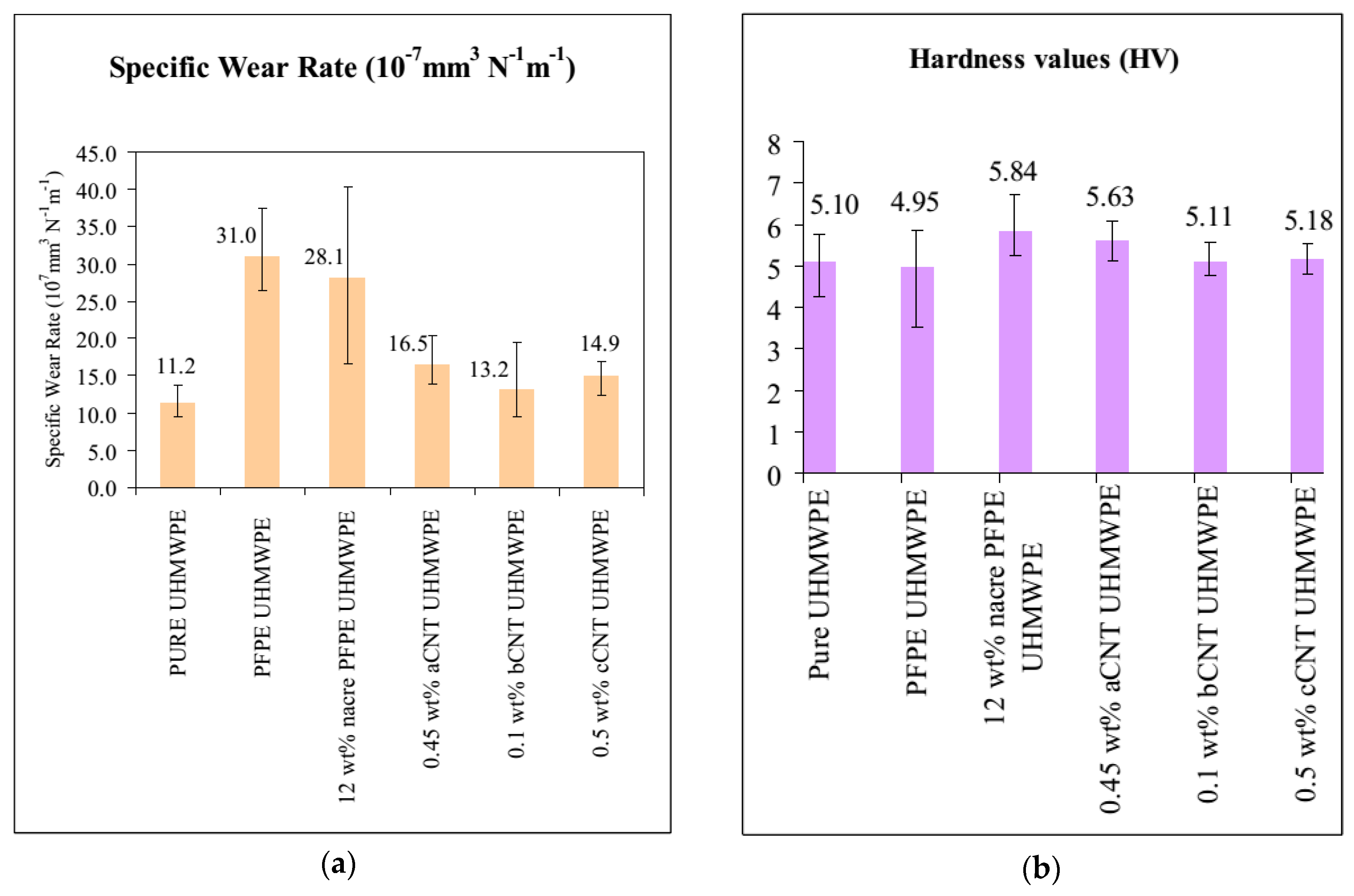

A Wear Rate For Different Uhmwpe Composites B The Vickers Hardness Download Scientific Diagram

Polymers Free Full Text Ultra High Molecular Weight Polyethylene Uhmwpe As A Promising Polymer Material For Biomedical Applications A Concise Review Html

0 Response to "uhmw friction coefficient"

Post a Comment